AF-30 Feeder Photos

AF-30_010

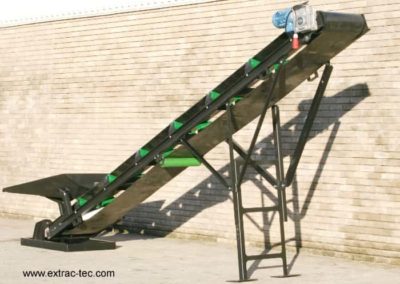

The AF-30 is a simplified, low-maintenance Feed Conveyor without a Hopper/Grizzly specifically designed for manual feeding of the HPC-30 in Artisanal and Small-Scale Mining Operations.

AF-30_020

The AF-30’s solid and open design supports the HPC-30 with adjustable speed to match the feed requirements of the HPC-30 whether processing fine or coarse material.

AF-30_030

Quick and easy to setup, the simple robust and reliable design allow versatility of feeding of an extremely broad range of materials in different operating conditions and applications.

AF-30_040

Full mobility – the conveyor fastens on top of HPC-30 whenever you need to tow your machine to a new location.

AF-30_050

The AF-30 is designed to accommodate installation in space-restricted areas with irregular terrain.

AF-30_060

The Feed Chute can be placed on or at the base of your material stockpile to minimize the work required for feeding.

AF-30_070

With multi-line installations the machines can be placed alongside one another to improve materials handling efficiency.

AF-30_080

The AF-30 is an extremely versatile feeder that is well suited to fine, sandy and coarse material sized up to 150mm / 6”

AF-30_100

Demanding materials including gravels containing a high percentage of sticky clay can also be processed.

AF-30_110

The AF-30 is specifically designed for manual feeding of the HPC-30 in Artisanal and Small-Scale Mining Operations. Feed rate is primarily determined by the rate at which material is loaded into the Feed Chute.

AF-30_120

The most efficient configuration is to build your material stockpile alongside the AF-30 so that material can be shoveled directly into the Feed Chute with minimal effort.

AF-30_140

The robust, open Feed Chute is large enough for material to be staged just prior to feeding onto the conveyor. The rear lip of the Chute is designed for easy attachment of a small loading ramp.

AF-30_150

A solid frame supports the Feed Chute and Conveyor and automatically allows the conveyor to rotate to any required inclination.

AF-30_180

Troughed conveyor idlers prevent material from spilling off the conveyor belt. Idler brackets are designed for easy maintenance of idlers.

AF-30_190

A self-tensioning Belt Scraper installed on the inside of the conveyor belt, helps to keep Idlers and Pulleys clean.

AF-30_210

Conveyor Support Legs maintain stability of the conveyor and can be set to suit the terrain and inclination of the conveyor.

AF-30_220

The Drive System is mounted at the end of the conveyor belt, a safe distance away from the Feed Chute.

AF-30_230

A digital controller which controls the conveyor belt speed can also be used to control the rate at which material is fed to the HPC-30.

AF-30_240

The Digital Controller and Circuit Breaker are housed in a Waterproof Electrical Cabinet which can be mounted on the HPC-30 or separately.