HPC-15 Photos

HPC-15_010

The HPC-15 is a complete and fully mobile recovery system offering unbeatable capability for recovery of gold, gemstones and other minerals.

HPC-15_020

The mobility and capacity of the HPC-15 make the machine ideal for exploration, bulk sampling, startup and artisanal mining operations.

HPC-15_030

A fully adjustable Feed Conveyor is integrated into the machine to ensure perfect feed rate for maximum recovery rate with high productivity.

HPC-15_040

Robust construction, simple operation and compact design make the HPC-15 an ideal machine for remote, hard-to-reach locations.

HPC-15_050

The HPC-15 is extremely versatile and ideally suited to exploration projects tasked with establishing the viability of a wide range of mineral recovery projects.

HPC-15_060

The Scrubbing & Screening Trommel installed in the HPC-15 facilitates simple and effective washing and classifying of a broad range of materials.

HPC-15_070

The trailer-mounted HPC-15 is completely mobile. The machine can easily be towed by a small pickup truck (total weight is approximately 1.8 tons).

HPC-15_080

The integrated Feed Conveyor is key feature of the HPC-15 offering many advantages including consistent feed rate for optimal recovery and high operational efficiency.

HPC-15_090

The Grizzly prevents larger rocks from entering the Feed Hopper. The Grizzly can be detached if required.

HPC-15_100

Material is held in the Feed Hopper from where it is discharged onto the Feed Conveyor. The Hopper holds enough material to feed the HPC-15 without interruption whilst operators attend to other tasks.

HPC-15_110

A Choke Plate is installed on the Feed Hopper Gate. This plate can be installed or removed to control the restriction of material feed from the Hopper onto the conveyor belt. Typically the Choke Plate is installed when feeding fine material and removed when feeding coarse material.

HPC-15_120

Material falls from the Feed Conveyor belt into the Trommel Feed Chute where it is washed into the Trommel. Water flow into the Feed Chute is independently controlled at the Water Manifold.

HPC-15_130

Water supply to the HPC-15 is fed into the Water Manifold. The Water Manifold allows independent control of water flow throughout the HPC-15. Extra outlet valves are included for a general purpose hose and for any auxiliary equipment that requires water.

HPC-15_140

Material from the Feeder is washed into the high-rpm Trommel where it is thoroughly scrubbed and screened.

HPC-15_150

The Trommel is supported on two sets of heavy-duty casters. Caster brackets are designed to allow for easy maintenance.

HPC-15_160

The Trommel Scrubber is divided into 2 sections, each with 3 lifting paddles. Material washed into the Trommel is retained in each section to allow thorough tumbling and washing of rocks, gravel, sand and clay before screening.

HPC-15_170

Scrubbed material passes from the Trommel Scrubber section to the Trommel Screen. Fine / undersize material falls through the screen whilst large / oversize gravel and rocks are retained and fed to the Discharge Section of the Trommel. Lifters inside the Trommel Screen and additional water sprayed into the screen ensure that all fine particles are discharged through the screen.

HPC-15_180

The Trommel Screen is bolted into the Trommel and can be removed and replaced if required. This allows for easy installation of different screen sizes if needed.

HPC-15_190

Oversize material is fed from the Trommel Screen to the Discharge Section where it is discharged from the machine. The water nozzle at the rear of the Trommel sprays water into the Screening Section of the Trommel to assist with the washing process. The Discharge Section is also fitted with a Nugget Trap to retain nuggets which have not passed through the Trommel Screen.

HPC-15_200

Oversize material discharged from the Trommel falls onto the Oversize Chute. These rocks and gravel form a pile at the back of the machine which must be cleaned up as required

HPC-15_210

Fine / undersize material washes through the Trommel Screen, falls into the Material Distribution Chute and is then washed onto the Concentrator Belt. The Chute can be adjusted to precisely control where material is discharged onto the Concentrator Belt. This allows for additional control of mineral recovery and yield in certain applications.

HPC-15_220

The reverse spiral Concentrator Belt is a unique feature of the EXTRAC-TEC HPC Technology. The Concentrator Belt enables complete control of the fluidization of material with long retention time for unbeatable recovery of heavy particles by gravity separation (see videos for a detailed presentation ).

HPC-15_230

Additional control of material fluidization on the Concentrator Belt is achieved through the Vibration Roller and Belt Washbar. Vibration of the Concentrator Belt assists with settling of heavy particles whilst independent control of water flow onto the Concentrator Belt ensures correct control of material fluidization (slurry / pulp density).

HPC-15_240

The Concentrator Belt separates heavy and light particles. Heavy particles are then washed onto the Concentrate Sluice. Rotation and Inclination of the Concentrate Sluice can be adjusted for optimum recovery of heavy particles.

HPC-15_250

The Concentrate Sluice has 4 recovery sections, each containing a Concentrate Mat, Riffles and a Riffle Lock. During periodic cleanups, Concentrate Mats are taken out of the sluice to remove heavy concentrate.

HPC-15_260

Light particles are washed off the Concentrator Belt onto the Tail Sluice. Analysis of heavy particle recovery in the Tail Sluice is used to provide feedback on whether the machine setup is correct / optimal or not.

HPC-15_270

Brackets are provided on top of the HPC-15 to attach the Concentrate Sluice when towing the machine.

HPC-15_300

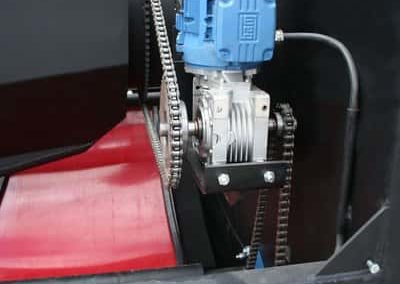

The drive motor and gearbox are mounted on an adjustable bracket and located behind a safety cage.

HPC-15_310

Tensioning bolts on the Drive System mounting bracket allow for easy tension adjustment of the drive chains.

HPC-15_320

The Feed Conveyor Drive System is mounted on the side of the conveyor. The drive chain is protected by a safety cover.

HPC-15_330

Switches mounted on the Electrical Control box independently control the Drive Systems. The water and dust-proof control box protects electrical components housed inside.

HPC-15_340

Electrical controllers enable precise speed control of the Feeder, Trommel and Concentrator Belt. After initial setup, the Control Box can be locked – only the On/Off switches are required for day-to-day operation.

HPC-15_350

Heavy-duty bearings are used throughout the HPC-15. Maintenance involves regular lubrication only.

HPC-15_370

The Belt Washbar is fitted with a purge valve to allow for easy flushing of dirt from the water circuit.

HPC-15_400

The 2 storage areas at the front of the HPC-15 Trailer offer room for storage and transportation of your extra equipment and supplies.

HPC-15_410

A water pump, generator, tools, fuel and other auxiliary equipment can easily be secured and transported on the Trailer.

HPC-15_420

The Jockey Wheel at the front of the Trailer is not only useful for hitching the HPC-15 to a vehicle – it is also used to easily adjust the inclination of the entire machine during set-up.

HPC-15_430

The machine is fitted with 4 Landing Legs. These are locked in place once the HPC-15 is set-up so that the entire machine is stable and secure.

HPC-15_440

The HPC-15 Trailer is fitted with and adjustable Tow Hitch bracket which allows different hitches to be used – Pintle Hitch fitting installed in this image.

HPC-15_450

The HPC-15 Trailer is fitted with and adjustable Tow Hitch bracket which allows different hitches to be used – Ball Hitch fitting installed in this image.

HPC-15_460

International shipping of HPC-15 machines is easy – the machine is transported in a 20′ container with plenty of room for additional equipment such as a water pump and electrical generator.

HPC-15_475

Completed machines ready for shipping (middle machine with pump and generator secured on Trailer).