HPC-30 Photos

HPC-30_010

The HPC-30 Heavy Particle Concentrator is one of the most advanced gravity recovery systems available and is the ideal solution for small-scale and start-up mining operations.

HPC-30_020

The HPC-30 is suitable for a broad range of heavy particle concentration applications and is capable of processing up to 30 tons per hour, depending on the gravel composition. Refer to specifications sheet for more information.

HPC-30_030

This view of the HPC-30 shows the Concentrate Sluice, Tail Sluice and Oversize Tailings Chute in operating position. Sluices and Chutes are easily stowed when the machine is towed or shipped.

HPC-30_040

The HPC-30 achieves an unbeatably high concentration ratio. Only 5 litres (1.3 gallons) of concentrate are produced every cleanup – even after a full day’s production.

HPC-30_060

Rear view of HPC-30 showing sluices and attachments folded up and stowed for shipping or towing.

HPC-30_070

The HPC-30 recovery unit is offered with a choice of feed systems to accommodate a broad range of applications, sites and operating conditions. The AF-30 (artisanal feeder) shown here, is a simplified Feed Conveyor without a Hopper/Grizzly, designed for manual feeding of the HPC-30 in Artisanal and Small-Scale Mining Operations.

HPC-30_080

The HPC-30 recovery unit is offered with a choice of feed systems to accommodate a broad range of applications, sites and operating conditions. The FC-30 (mobile feed conveyor) shown here, is a Feed Conveyor with Hopper and Grizzly, designed for use with the HPC-30 with material that is not sticky and has low clay content. It can be fed with an excavator, backhoe or small loader.

HPC-30_090

The HPC-30 Feed Chute is designed to receive -150mm material from a conveyor and feed it into the scrubbing section of the Trommel.

HPC-30_100

The angled design of the Feed Chute accommodates a variety of feed rates and material types.

HPC-30_110

The Feed Chute’s independently controlled water inlet washes material into the Trommel and provides water for scrubbing.

HPC-30_120

The high-rpm Scrubbing / Screening Trommel thoroughly washes and screens material so that undersize/valuable fraction is processed whilst oversize waste is rejected as tailings.

HPC-30_130

Trommel speed and inclination are adjustable to ensure maximum effectiveness and efficiency.

HPC-30_140_

The Trommel can be lifted and lowered for optimal position and access during operation, maintenance and transportation.

HPC-30_150

The Trommel scrubber has 3 chambers to maximise scrubbing retention time and material lifters for aggressive material washing action.

HPC-30_160

The Trommel screen classifies material so that smaller, mineral-rich particles are processed whilst oversize waste is rejected.

HPC-30_170

The screening section comes standard with a 6mm (1/4″) screen and can be customized for specific applications as needed. The modular design allows for easy screen replacement should the screen get worn or if a specific screen size is required.

HPC-30_190

Two spray nozzles are independently directed to maximize rinsing of material in the screening section.

HPC-30_200

Four sets of heavy duty casters ensure adequate support plus smooth rotation and tracking of the Trommel at low and high rotational speeds.

HPC-30_220

The Trommel Drive System components comprise of robust internationally recognized brands. The Gearbox position is easily adjustable to maintain proper chain tension at all times. Trommel speed is independently controlled by a dedicated Variable Speed Drive.

HPC-30_240

The Trommel inclination can be adjusted for process optimization – typically flatter for materials requiring longer retention time in scrubbing/screening sections.

HPC-30_250

The Trommel is easily lifted with a 4-ton hydraulic jack which is included in the machine’s spares kit. This easy, low-tech solution requires minimal equipment.

HPC-30_260_

Once the correct Trommel position and inclination are found, the Trommel can be pinned in place.

HPC-30_280

The Oversize Chute directs oversize tailings discharged from the Trommel away from the back of the machine so that these can easily be removed for disposal.

HPC-30_290

Our internationally patented reverse-helix Concentrator Belt ensures unbeatable recovery of liberated gold and heavy particles, eliminating the need for any chemicals or mercury.

HPC-30_310

The Concentrate Sluice features 4 recovery sections optimized to provide ultra-high concentration ratios with an unbeatable recovery rate.

HPC-30_330_

The first part of the Concentrate Sluice is a stilling section which smooths material flow into the recovery sections. Water flow to the sluice is independently controlled.

HPC-30_340_

Sluice inclination and angle of rotation are easily adjusted to suit processing conditions.

HPC-30_350

The Tail Sluice serves as a very useful process calibration tool, especially during initial setup. Regular checks quickly indicate incorrect feed rate, machine inclination, water flow rate and other settings.

HPC-30_360

The Tail Sluice consists of riffles, riffle locks and retention mats and is removable for easy storage during transportation.

HPC-30_370

The Independent Belt Drive System components comprise of robust internationally recognized brands. The Gearbox position is easily adjustable to maintain proper chain tension at all times. Speed is controlled by a dedicated Variable Speed Drive.

HPC-30_380

The vibration roller agitates material on the Concentrator Belt which further aids the settling and recovery of heavy particles.

HPC-30_400

The main Washbar helps fluidize material and keeps the belt clean. The nozzles are independently controlled and can easily be adjusted to customize flow rate depending on desired material pulp density.

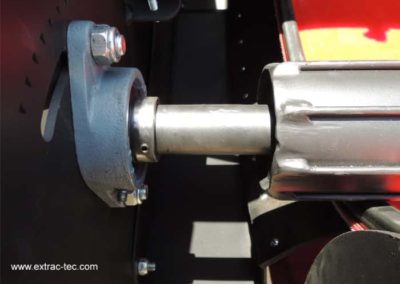

HPC-30_420

High quality flange bearings are used to secure the rollers to the HPC-30 frame. The bearings are easy to maintain and are readily available should they require replacement.

HPC-30_430

Easily removable Safety Cages at the front of the HPC-30 offer protection from moving parts during operation.

HPC-30_450

The removable Pintle Hitch and safety chain allows the HPC-30 to be connected to almost any type of towing vehicle.

HPC-30_460

Two sets of heavy-duty axles and wheels are installed for transportation and mobility on site. These can easily be removed and stored, once the landing legs are in place.

HPC-30_500

Once the electrical controls have been set, the box can be locked as the operator only needs to access the externally mounted on/off switches for the Feeder, Trommel and Concentrator Belt.

HPC-30_520

Water Control Manifold with valves for independent control of water flow to each section of the machine.

HPC-30_530

Mobility means easy placement on site which allows for quick setup and commissioning. It is extremely easy to move these units around on-site and closer to stockpiles to minimize material handling costs.

HPC-30_540

The HPC-30 is an extremely versatile concentrator which can be used in a broad range of mineral exploration activities, configurations and production applications.

HPC-30_550

Our equipment is made from high quality components which will withstand the most extreme conditions. Equally our robust design has made it possible for units to run non-stop 24/7 to optimize production

HPC-30_560

HPC machines can be fed with re-circulated water provided the water is free of larger suspended particles which block smaller water nozzles. A series of settling ponds is a simple way of implementing a water recirculation circuit.

HPC-30_570

Customized HPC-30 machines are available for pre-concentration applications where material is pre-classified and the scrubbing/screening trommel and sluices are not required.

HPC-30_580

Transportation of the equipment is effortless due to mobility of machines which can be loaded and offloaded with a normal loading ramp.

HPC-30_590

The HPC-30 fits into a 20′ Container for shipping. It can be shipped with the AF-30 feeder in a 20′ container or in a 40′ container with a FC-30 feeder. Equipment can be loaded and offloaded from the container with a normal pick-up truck. Containers can be purchased for use as a storage facility on-site.